At Universal Metal Products, our focus is on custom metal stampings. Our creative team of engineering experts is always busy dreaming up a better way – whether your solution calls for a robust stamping, high heat resistance, extended corrosion performance, minimal clearance or stack ups, fast assembly, one-piece construction or bottom-line cost savings.

Although we’ve been an industry leader in custom metal manufacturing for over 78 years, we provide much more than pieces parts to our customers. We provide full service partnership.

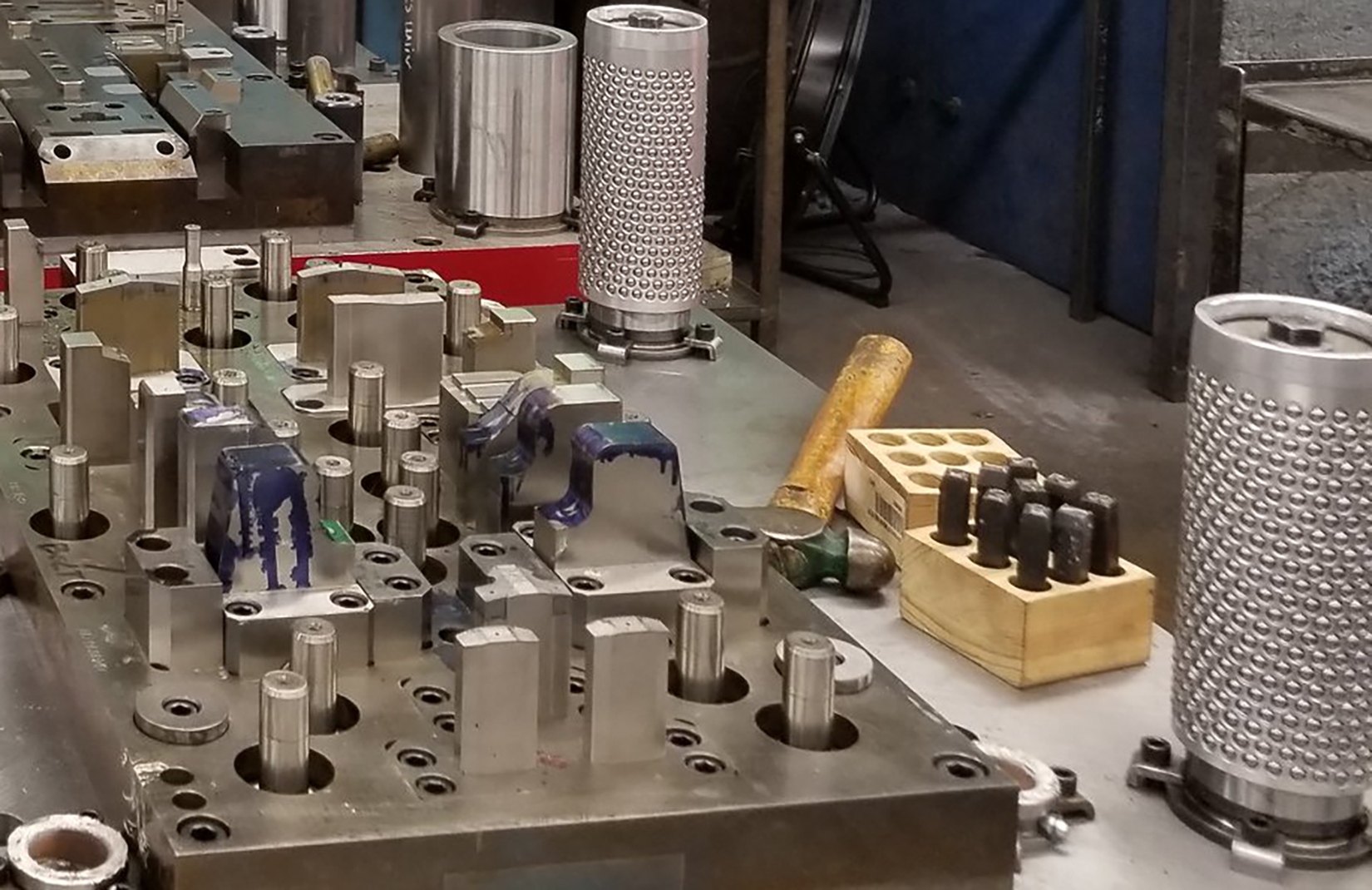

Sure, we have fourslide, multi-slide and punch-press equipment, but anyone can have equipment. It’s knowing exactly what to do with it that makes a difference. Knowing exactly what the equipment can and cannot do with particular grades of steel and geometry. Knowing how to engineer and re-engineer component parts. Knowing how to push the manufacturing process to create the perfect component for your specific application. That is what we do best. We call this approach to problem solving “solutions engineering.” That is what Universal Metal Products is all about.

For a complete list of our equipment and capabilities, please contact us at: solutions@ump-inc.com

Welcome to the on-line home of Universal Metal Products. Here you will find everything you need regarding custom metal stampings. Universal’s extensive metal forming experience ranges from complex Fourslide and Multislide to light, medium and heavy duty Punch Press operations.

Specializing since 1946 in high volume appliance, automotive and industrial metal stampings, Universal can fill almost any metal stamping need.

1946 → Universal Metal Products founded

1950’s → The UniClamp, Universal’s industry leading hose clamp is born

1987 → Universal Metal Products is acquired by current ownership

1997 → Hercules Stamping is acquired by Universal Metal Products to expand progressive die punch press capabilities. aka UMP Toledo, OH

2000 → Wickliffe, OH facility expansion and relocation of heat treat operations to optimize material flow

2001 → Wickliffe, OH facility adds (2) wire EDM machines

2003 → Appliance OEM’s step up migration from US based operations into Mexico

2004 → Company expanded operations again through the addition of a purchased building in McAllen, TX. The 30,000 sq ft facility was intended to support existing and new customer migrations to Mexico. Facility can be expanded up to 240,000 sq ft as required

2004 → UMP McAllen opens 30,000 sq ft facility with dedicated progressive die punch press operations

2004 → Wickliffe facility adds (1) wire EDM machine to existing footprint

2005 → McAllen facility adds (1) 400 ton press to existing footprint

2005 → Universal focuses attention on balanced diversification with Appliance, Vehicle and Industrial segments targeted

2005 → Whirlpool acquires Maytag resulting in the closing of nine Maytag/Whirlpool facilities from 2005 to 2012

2006 → UMP McAllen expands to 60,000 square feet. Operations expand to include value added processing

2006 → UMP McAllen adds (1) 600 ton press to increase tonnage capability

2006 → Class 8 trucking record year for NAFTA production

2007 → UMP Pemberville adds (2) 600 ton presses to increase tonnage capability

2010 → UMP Pemberville adds (2) additional 600 ton presses to current footprint

2017 → Wickliffe facility acquires new CNC milling equipment to help facilitate existing internal die building capabilities

2017 → Wickliffe facility upgrades TS16949 to new IATF16949:2016

2018 → Pemberville and Pharr facilities upgrade TS16949 to new IATF16949:2016

2018 → CNC milling operations start at UMP Wickliffe

2019 → CNC lathe capability added to UMP Wickliffe

2020 → UMP certified by WBENC as Women Owned

2020 → UMP Wickliffe, OH expands CMM capability in QC

2021 → UMP celebrates 75 years in metal forming

2022 → Expanded process automation team

2023 → Wickliffe, OH plant updates & Relacement of (2) CNC wire machines

2023 → Toledo, OH plant added 400 ton press is brought online for added capacity

2023 → Pharr, TX adds CNC milling capability

2024 → Toledo, OH plant added 600 ton press is brought online for added capacity

2024 → Pharr, TX facility adds (2) 600 ton presses

2024 → Creaform 3D scanning technology capabilities added to UMP Wickliffe, OH and Pharr, TX facilities

Universal Metal Products has three strategically located manufacturing facilities to insure that our production is close to your point of consumption helping to minimize ever rising logistics costs. All UMP facilities satisfy criteria for USMCA.

Universal Metal Products

29980 Lakeland Boulevard

Wickliffe, OH 44092

440.943.3040

Universal Metal Products

850 West Front Street

Pemberville, OH 43450

419.287.3223

Universal Metal Products

101 W. Eldora

Pharr, TX 78577

956.283.7200